Company Profile

-

1998year

was founded in

-

34item

Special and qualification certificates

-

6980door

partners

The headquarter of Xinglong Pump Industry is located in the beautiful northern suburb of Hangzhou, Pingyao Town, the birthplace of Liangzhu culture. The company occupies an area of 15,000 acres, with 11,000 acres of scientific research and production buildings. The company has advanced manufacturing and testing equipment, an innovative R & D team, and employees with junior college graduates of 30%. It is a nationally recognized high-tech enterprise. The company has passed CCS quality system certification of China Classification Society and is a first-class material supplier of China National Petroleum Corporation.

The company is the deputy director unit of China Screw Pump Professional Committee, the drafting unit of the JB / T8644-2007 single screw pump standard, and the only drafting company of the HJ2524-2012 technical requirements for environmental protection products.

The coal water slurry screw pump produced by the company has obtained a number of national patents, and is known for its stable performance and wear resistance, and its national market share has reached more than 80%.

Product center

Hot model display

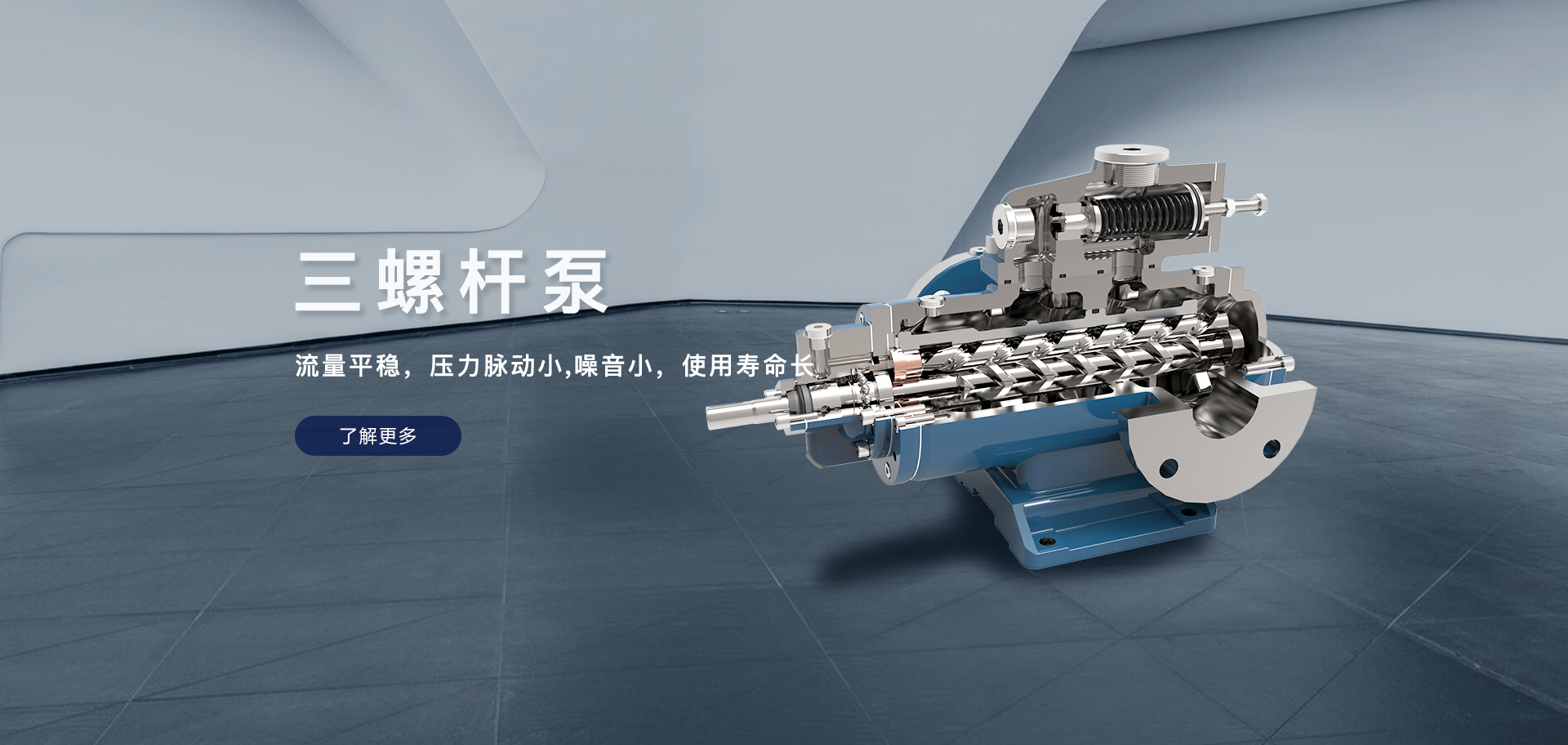

Job characteristics

Wide range of applications, can transport all hydraulic and even non-flowing materials, can be rotated in both directions and in both directions;

Flow pressure is stable without pulsation;

The flow is proportional to the speed and can be used as a metering input;

Low working noise and high efficiency.

understand moreApplication area

News Center

-

Company news

-

Industry news

-

Show information